Understanding the vibration behavior of rail structural components is crucial in railway machinery design. The XTOP3D XTDIC-SPARK high-speed 3D measurement system, comprised of a high-speed camera and dynamic analysis software, provides highly accurate displacement, velocity, acceleration, and other data, enabling full-field, high-resolution vibration measurement of the measured object within a range of markers and feature points.

Non-contact DIC technology vibration measurement requirements

To control and minimize the adverse effects of vibration, precise structural vibration measurement and analysis are necessary to better understand vibration characteristics and, consequently, implement targeted vibration control.

Contact vibration measurement methods, such as accelerometers, introduce additional loads during the measurement and wiring process, making sensor installation and wiring complex and potentially altering the dynamic characteristics of the structure.

In addition, non-contact vibration measurement methods, such as laser Doppler vibrometers, suffer from discontinuous single-point measurement points, poor full-field synchronization in scanning-based methods, and a short working distance.

The vibration measurement field requires measurement methods that are simpler to operate, offer more densely populated measurement points, extend working distances, achieve higher measurement efficiency, extend measurement ranges, and more intuitively reflect vibration conditions.

XTOP3D high-speed DIC measurement solution

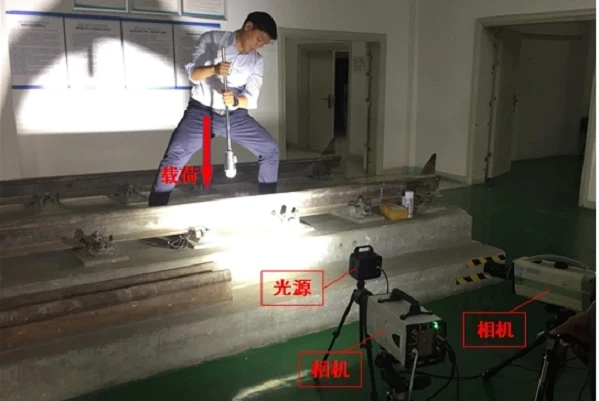

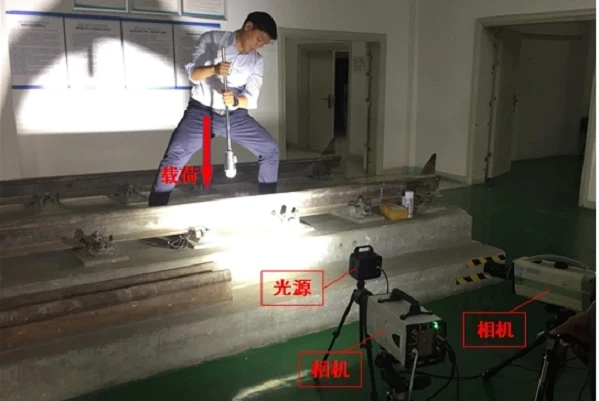

The XTOP3D XTDIC-SPARK 3D high-speed measurement system directly controls high-speed cameras to record the vibration displacement of structural components under various loading conditions, from static to dynamic. High-speed DIC is one of the most commonly used non-contact video vibration measurement methods.

Unlike accelerometers and laser diodes (LDVs), high-speed DIC uses a non-contact measurement method to generate instantaneous full-field displacement maps rather than single-point values. This method is generally faster, provides more comprehensive data, and is easier to use than traditional sensing methods.

In addition, compared to scanning laser Doppler methods, high-speed DIC offers lower costs, higher acquisition efficiency, and the ability to visualize full-field vibration measurements, making it a significant advantage for vibration measurement applications involving complex structures.