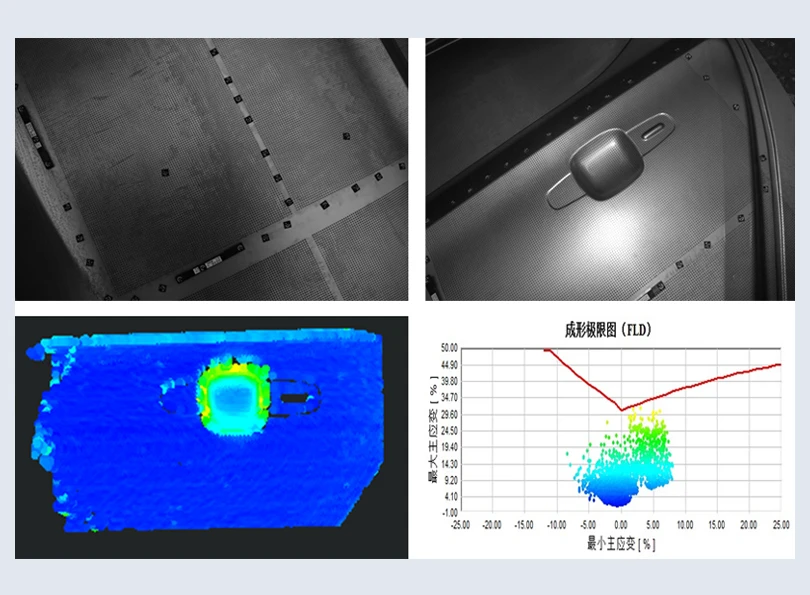

Strain measurement and analysis of sheet metal stamping

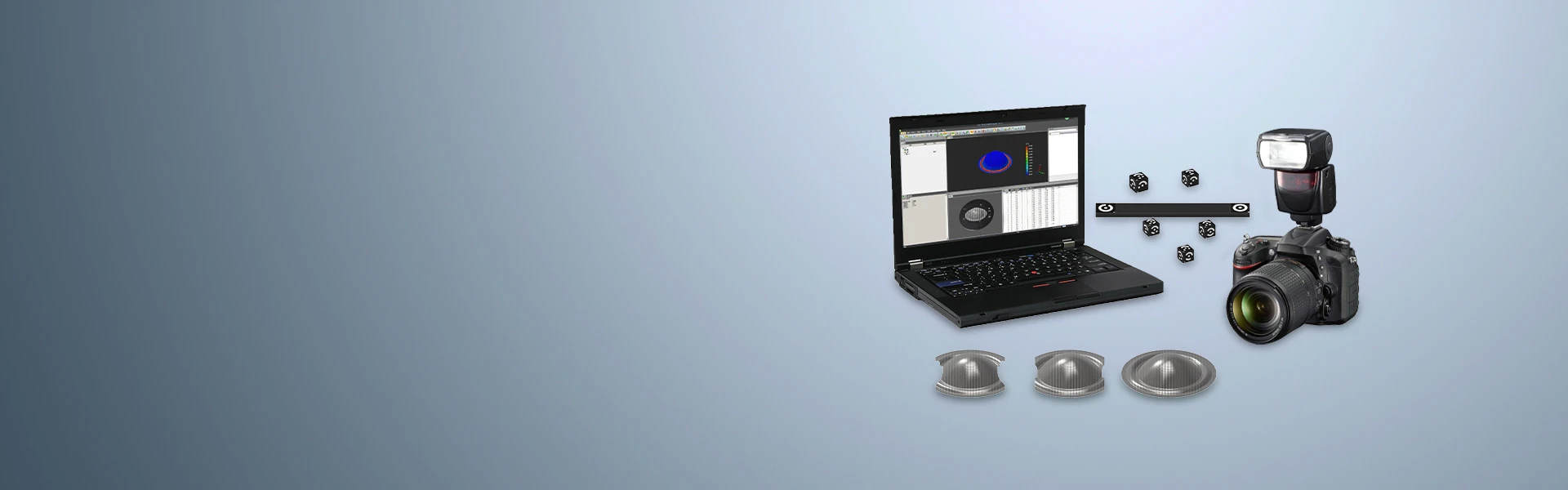

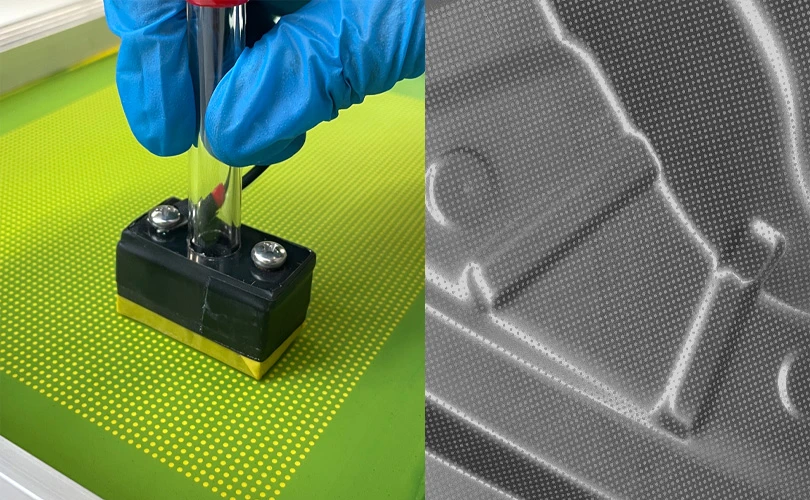

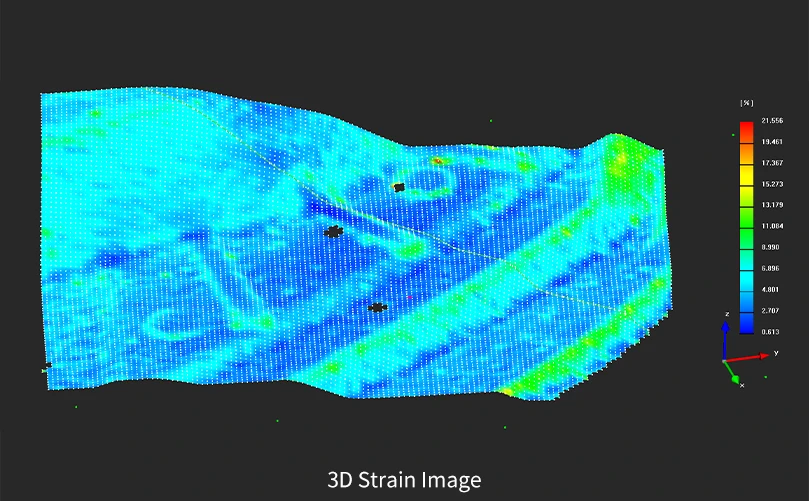

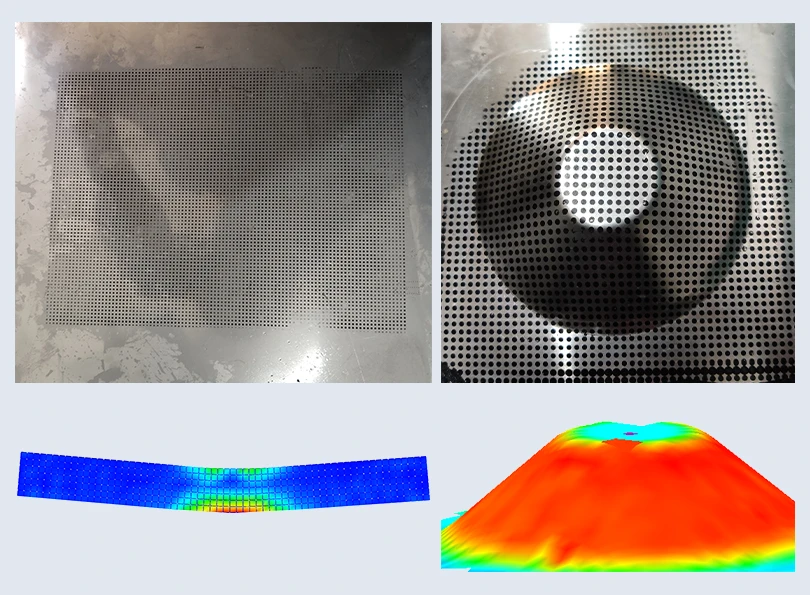

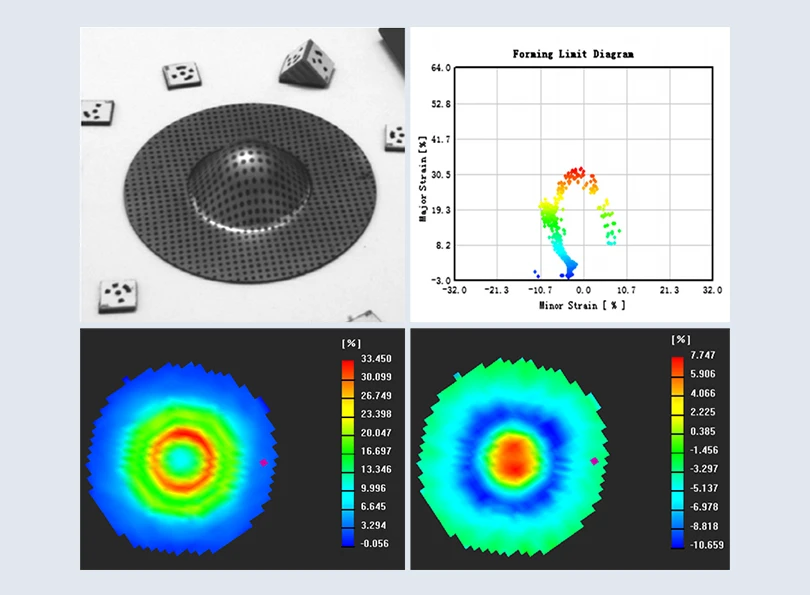

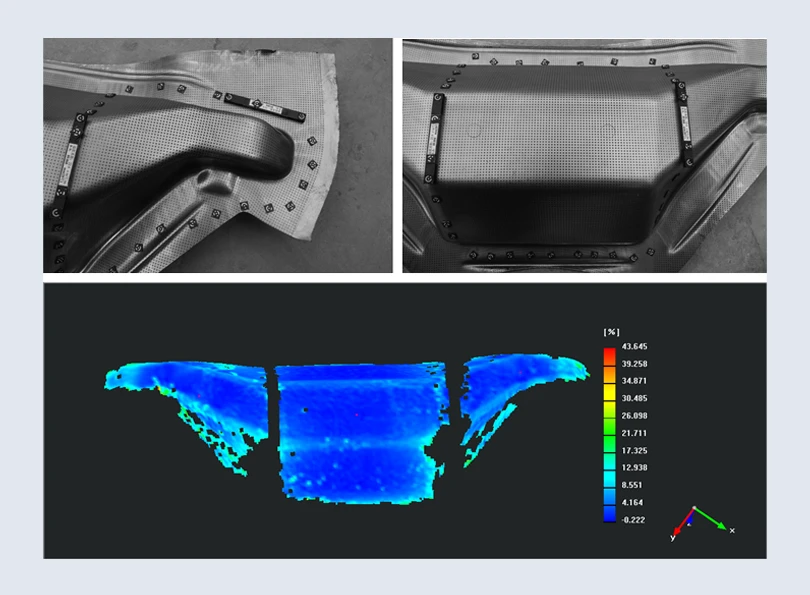

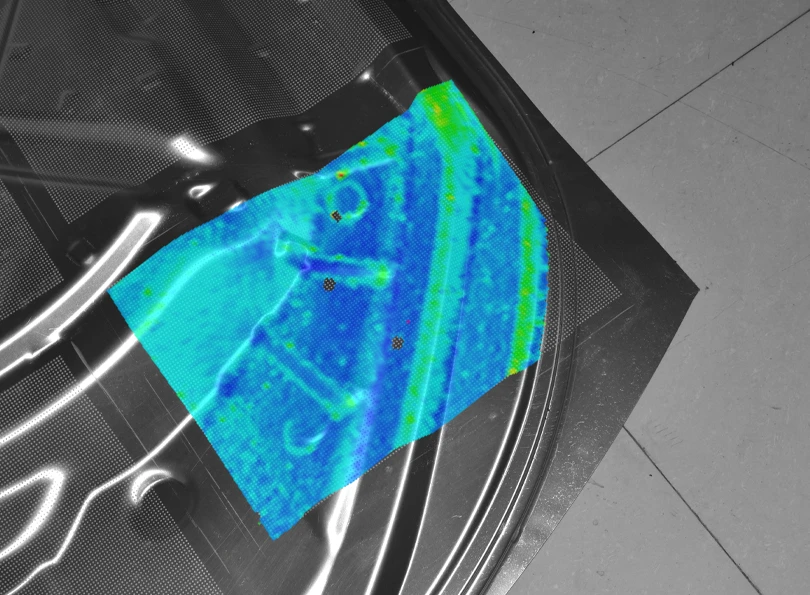

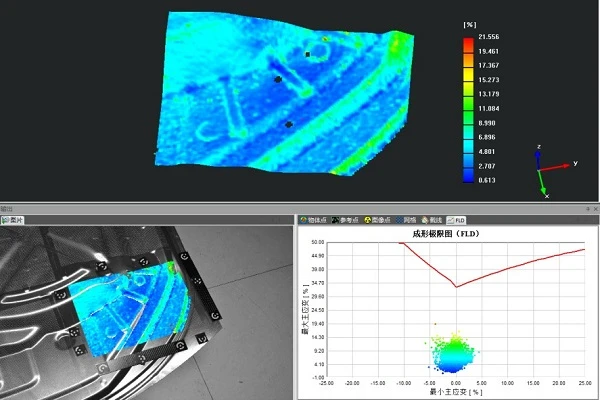

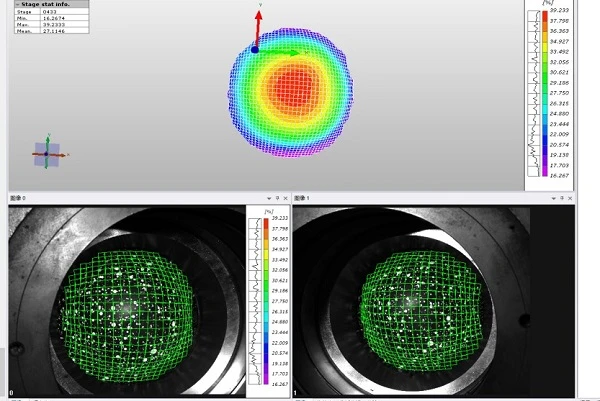

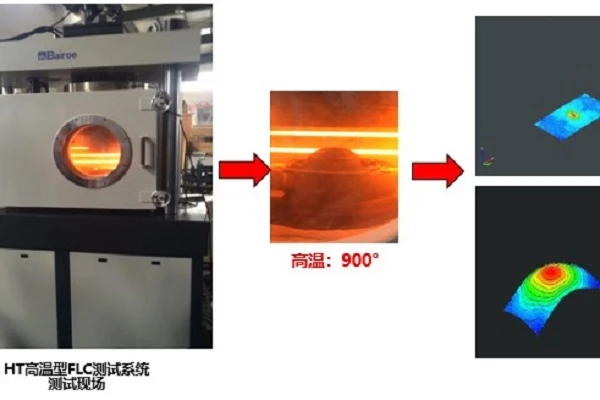

The XTDIC-SM sheet metal forming strain measurement system uses photogrammetry to obtain the three-dimensional coordinates of each circular point on the sheet metal surface, aligns grid points with the same name before and after stamping, and calculates the strain data at each grid point. By importing FLC curves, the system compares the distribution of the part's primary and secondary strain data and outputs an FLD diagram, quickly locating critical positions. It is an intuitive and efficient measurement tool for evaluating stamping processes.