For quantitative analysis of crack development and fracture morphology in similar material models during simulated advancement, the conventional approach is to capture fracture evolution images using a digital camera during mining, then describe and express them using manual sketches or digital image processing techniques such as image binarization. Binarization methods can affect image analysis and processing, sometimes losing image details and inaccurately extracting information about fine fracture morphology.

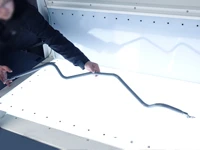

The XTOP3D XTDIC 3D full-field strain measurement system is a non-contact, full-field measurement technology. It acquires speckle images of an object under varying loads and then uses a correlation-matching algorithm for image analysis to quantitatively extract full-field displacement and strain response information. This information is used for full-field displacement and deformation measurement and quantitative analysis of crack development and fracture morphology.

Due to its non-contact, real-time dynamic measurement, and high resolution, DIC is widely used to study the fracture processes of standard rock samples and materials with defects such as pre-existing fractures. DIC technology can be used to study the displacement field of model deformation and extract and analyze model strain field information. It also has significant advantages in crack detection.

① For similar material models, due to their material heterogeneity, rough surface, and size significantly larger than standard rock samples, producing high-quality speckle fields on the model surface is particularly critical for test accuracy.

② DIC technology can optimize the sub-region size and spacing based on the test requirements of crack monitoring to improve test accuracy and reliability.

③ Through quantitative analysis of speckle pattern quality and optimization of DIC calculation parameters, a dual-parameter threshold method for sub-region size selection is adopted to address the heterogeneity of similar materials and the large, non-uniform deformation characteristics of the model.

By rationally setting up the DIC measurement system, producing the speckle pattern, and selecting parameters such as sub-area size and spacing, the generation and development of cracks can be effectively detected and quantitatively characterized in the application of similar material simulation test monitoring examples, providing data support for the study of crack development and failure morphology analysis in similar simulation tests.