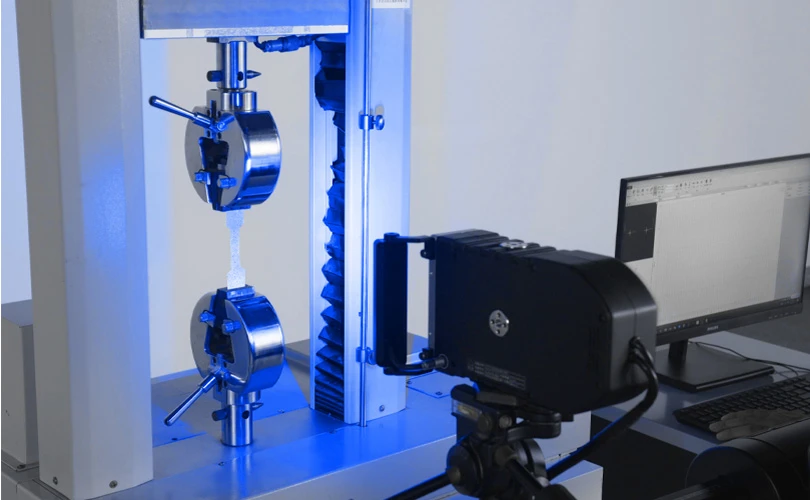

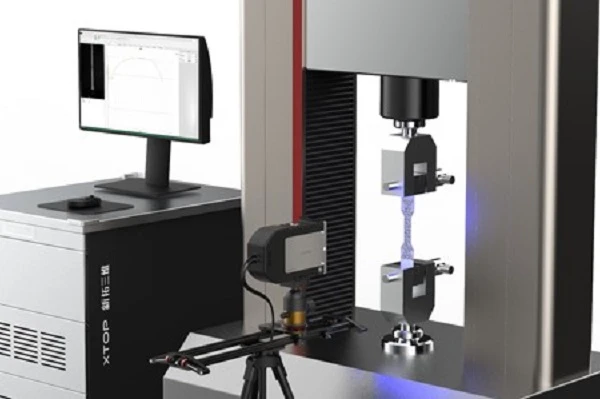

+Material performance testing

? Any material, especially suitable for small, flexible, and high-temperature applications

? Average value extensometer for more accurate material parameters

? Automatic peak and trough identification, better suited for long-term fatigue testing

+Large field of view multi-probe splicing solution

? Suitable for measuring materials over 600mm in length and with a wide field of view

? Developed multi-probe splicing technology to eliminate overall errors, achieving accuracy up to 0.5 video extensometer standards

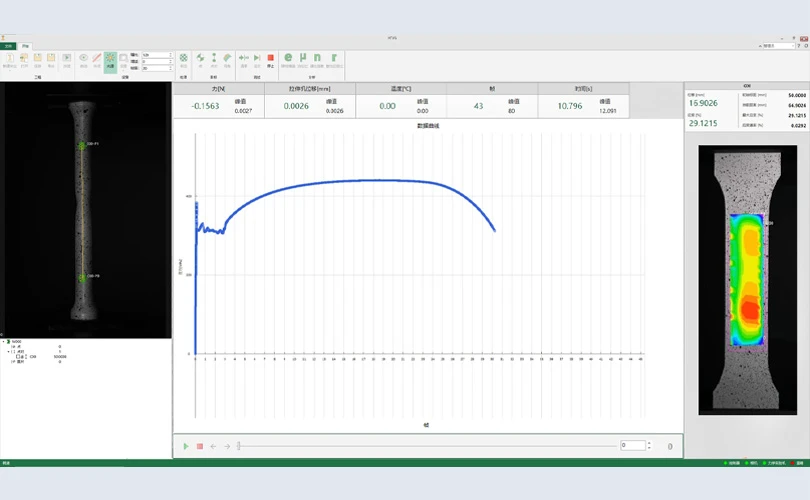

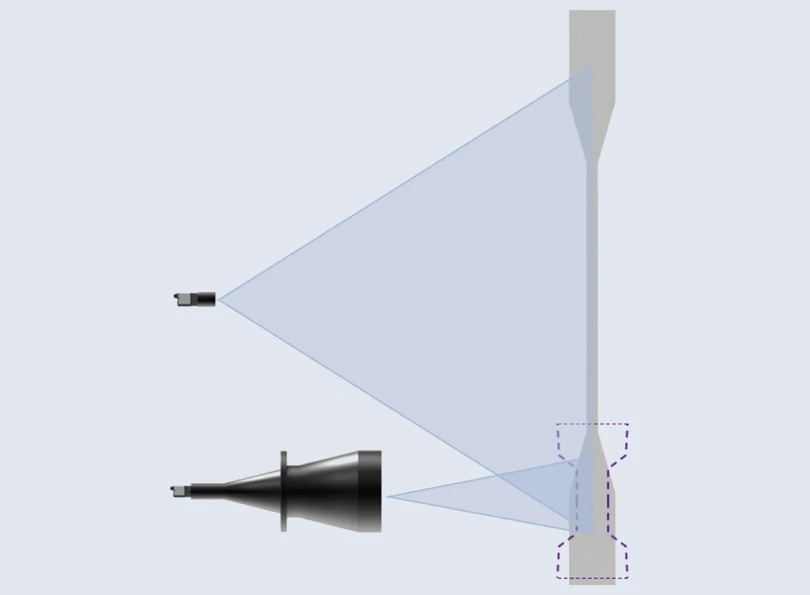

+Dual-range probe combination solution

? Suitable for stretching highly plastic materials such as rubber, gel, polymers, and carbon fiber

? In the low-strain stage, an independent camera and telecentric lens are configured to improve measurement accuracy

? In the high-deformation stage, another independent camera and standard lens are configured to record the entire deformation process of the material

? Feature stitching enables non-destructive stitching of the two measurement stages, achieving both low-strain, high-precision measurement and full-field uniformity of high-deformation measurement in a single measurement

+Multi-station simultaneous stretching solution

? Suitable for simultaneous tensile testing of multiple samples from the same batch

? Independent hardware for each channel

? Unified data display for easy comparison

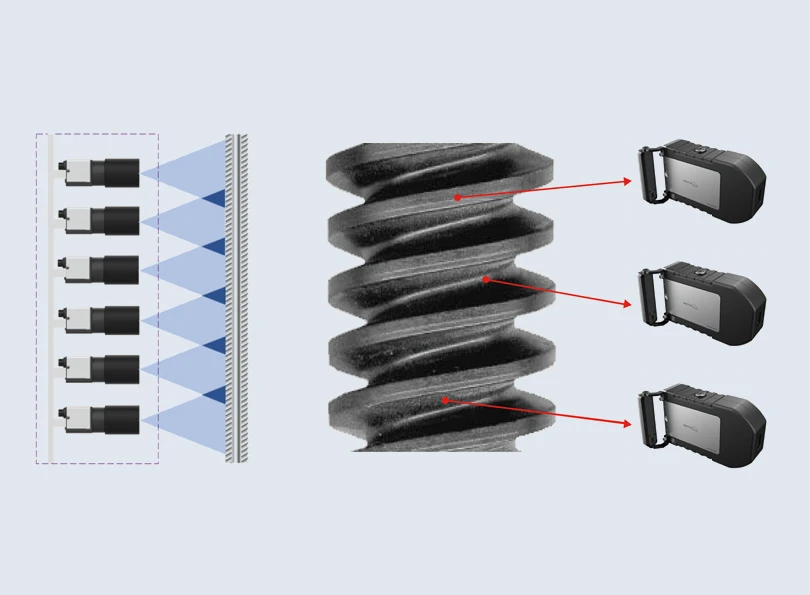

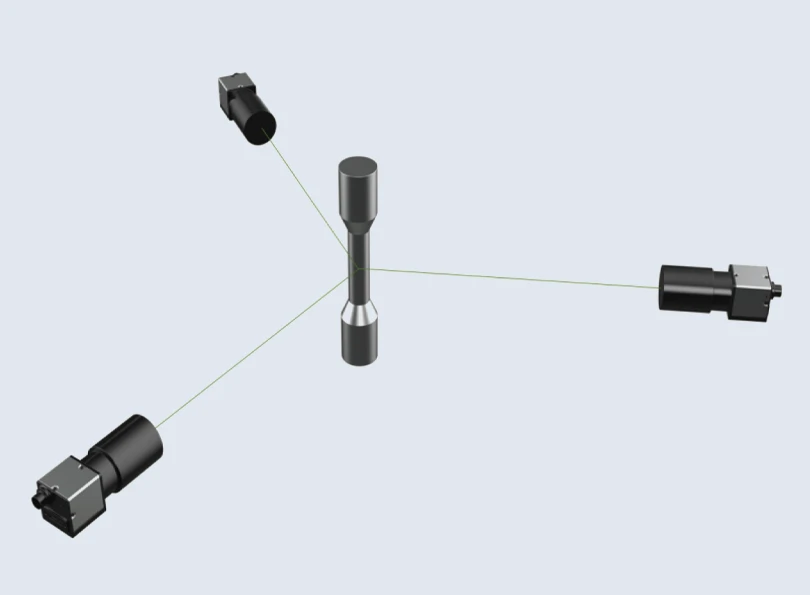

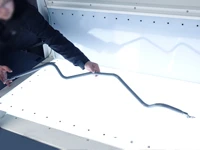

+Rod Profile Stretching 3600 Combination Solution

? Three probes, evenly spaced in the same horizontal plane, independently perform 2D data acquisition and analysis, calculating average tensile strain for more accurate results.

? Three probes, evenly spaced in the same horizontal plane, are used in combination to analyze the material necking state and cross-sectional parameter changes during the tensile process of rod-shaped profiles, such as the major and minor axes of the cross-sectional ellipse and roundness.

Watch Video

Watch Video