For civil engineering bridge materials, cracks and fractures occur when deformation reaches a certain level. This material deformation and fracture behavior under external loads is crucial for investigating the strength and durability of engineering structures. In the field of materials and structural testing, digital image correlation (DIC) has attracted considerable attention due to its sub-pixel accuracy, remote, multi-point non-contact testing capabilities, simple equipment, and easy operation.

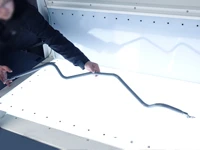

The XTOP3D XTDIC three-dimensional full-field strain measurement system utilizes digital image correlation (DIC) technology to directly measure the mechanical behavior of materials and structures. By measuring basic data such as displacement and strain fields on the material and structure surfaces, and using advanced DIC analysis software, it can quickly and comprehensively detect crack initiation location, size, propagation rate, and dynamic changes in the elastic-plastic phase, providing a convenient and reliable tool for researchers studying material strength and performance.

XTDIC Applications in Civil and Bridge Engineering

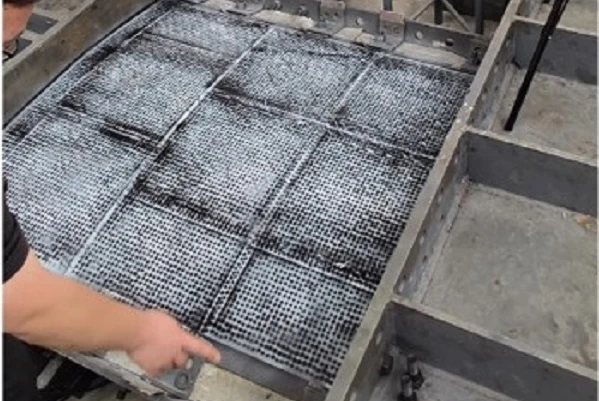

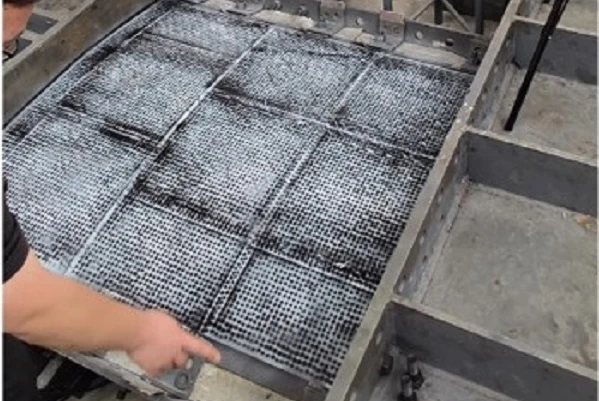

With increasing requirements for compressive, tensile, and shear strength in civil and bridge structures, functional and hybrid high-performance materials are increasingly being adopted. The XTOP3D XTDIC three-dimensional full-field strain measurement system can be applied to civil material mechanical analysis, structural analysis, dynamic displacement measurement, and surface deformation measurement of similar materials. It can test the tensile strength, crack resistance, fatigue resistance, and fracture toughness of civil and bridge structures, enabling quantitative analysis of material and structural mechanical properties, helping to scientifically and rationally improve the overall strength and durability of engineering structures.