XTOM high-precision 3D scanner for mold inspection and design verification

Date:2025-04-21

In modern manufacturing, mold precision and product quality inspection and verification are critical to ensuring production efficiency and product competitiveness. With the continuous advancement of technology, traditional inspection methods are gradually failing to meet the growing precision requirements.

Against this backdrop, the XTOP3D XTOM-MATRIX high-precision blue light 3D scanner, with its superior performance and wide applicability, has become a vital tool in mold manufacturing and product inspection and verification.

01. Applications in Mold Manufacturing

During the mold manufacturing process, the XTOM-MATRIX high-precision blue light 3D scanner can be used for:

· Mold design verification: Scan prototypes and molds to compare design data and ensure mold accuracy.

· Mold wear detection: Regularly scan molds to analyze wear and tear, enabling timely maintenance and repair.

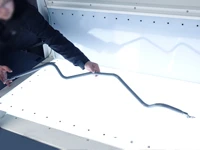

· Reverse engineering: Scan existing products to quickly obtain 3D models for mold design and product improvement.

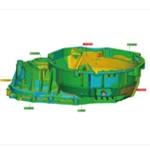

Mold Cavity Machining Quality Measurement

Mold Insert Deformation Detection

02. Applications in Product Inspection and Verification

In product inspection and verification, the XTOM-MATRIX high-precision blue light 3D scanner can be used for:

· Quality Control: Rapidly inspect finished products to ensure they meet quality standards.

· Dimensional Inspection: Accurately measure product dimensions, compare them with design data, and identify deviations.

· Shape and Contour Analysis: Analyze product shapes and contours to assess their consistency with the design.

Product Scanning, Reverse Modeling, and Deviation Detection

The XTOM-MATRIX high-precision blue light 3D scanner not only improves the efficiency and accuracy of mold manufacturing and product inspection and verification, but also provides an efficient, non-contact inspection method for the manufacturing industry and strongly supports its digital transformation.

By utilizing advanced optical measurement technology, the XTOM-MATRIX high-precision blue light 3D scanner is helping more and more companies stand out in the fiercely competitive market, ensuring product quality while also improving production efficiency and economic benefits.