The 9th Asia-Pacific Congress on Computational Mechanics (APCOM2025) will be held in Brisbane, Queensland, Australia, from December 7 to 10, 2025.

This symposium aims to convene experts, researchers, scholars, and practicing engineers focusing on machine learning methodologies in computational mechanics, to showcase their latest research findings, methodological advancements, and innovative applications. Specific areas of focus include leveraging advanced machine learning algorithms to enhance the accuracy of computational models, improving computational efficiency via hybrid computing strategies, and processing large-scale heterogeneous data to bolster the safety and reliability of engineering structural health monitoring.

Xtop 3D was invited to participate in the exhibition and debuted its advanced XTDIC-CONST Series 3D full-field strain measurement system to great acclaim. This system is widely applied in the characterization of mechanical properties across disciplines such as material mechanics, structural and vibration mechanics, fracture mechanics, impact mechanics, and micro-nano mechanics—enabling the assessment of mechanical parameters including strength, stiffness, plasticity, elasticity, and ductility. Through 3D-Digital Image Correlation (3D-DIC) technology, it enables continuous and comprehensive measurement of deformation and strain in materials and structures under loading, thereby facilitating the accurate acquisition of mechanical performance data.

Compared with traditional contact-based strain measurement techniques, the XTDIC 3D Full-Field Strain Measurement System offers distinct advantages in specialized scenarios such as mechanical property testing of flexible materials, measurements under high-temperature/high-pressure environments, large-deformation analysis, complex deformation processes, and strain measurement of micro-scale specimens.

The XTDIC-CONST Series 3D full-field strain measurement system is extensively utilized in mechanical property characterization, with key application scenarios and advantages outlined below:

1. Mechanical Property Testing of Materials

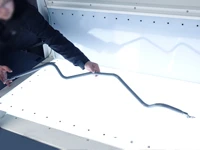

? Tensile, compressive, bending, and shear tests: It enables precise measurement of full-field displacement and strain distributions under diverse loading conditions, facilitating the derivation of mechanical parameters including elastic modulus, Poisson’s ratio, ultimate strength, and elongation at break.

? High-temperature/high-pressure environment testing: Through specialized optical design and surface treatment, DIC technology can measure material deformation under extreme conditions such as high temperatures (e.g., 2300°C) and high pressures—supporting performance evaluation of high-temperature-resistant materials in aerospace, energy, and other critical fields.

? Measurement of micro-specimens and complex structures: It enables full-field strain measurement of millimeter-scale micro-specimens or irregular/hollow structures (e.g., 3D-printed composites, automotive air springs), providing data support for micro-mechanical behavior analysis and structural optimization.

2. Crack and Damage Analysis

? Crack initiation and propagation monitoring: Real-time full-field strain contour maps capture the initiation location, propagation path, and rate of cracks, while analysis of stress field distributions at crack tips provides critical insights for fracture mechanics research and structural reliability assessment.

? Quantification of damage evolution: In fatigue and impact tests of materials such as concrete and rock, DIC tracks strain concentration and propagation in damaged regions, enabling evaluation of damage tolerance and residual strength.

3. Research on Dynamic Mechanical Behavior

? High-speed impact and vibration testing: Integrated with high-speed cameras, DIC achieves dynamic deformation measurement at millisecond or even microsecond resolution—applicable to scenarios such as automotive collisions, explosion impacts, and seismic simulations, enabling analysis of strain rate effects and energy absorption characteristics under high-speed loading.

? Fatigue life prediction: Long-term strain monitoring during dynamic loading tests establishes relationships between strain amplitude and cycle count, providing a data foundation for fatigue life prediction and engineering structural design.

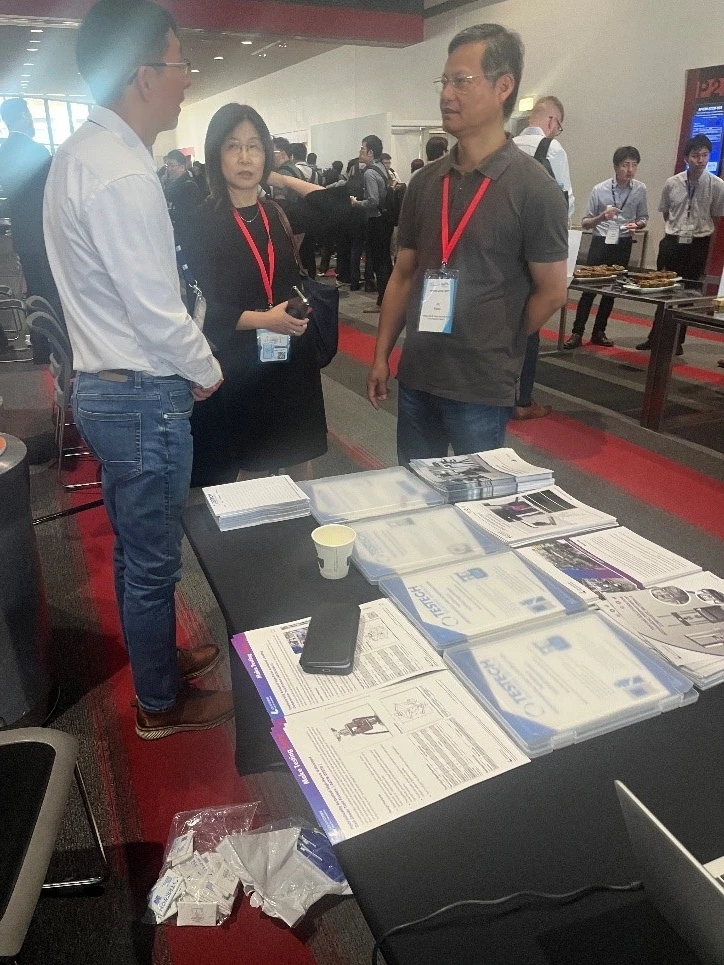

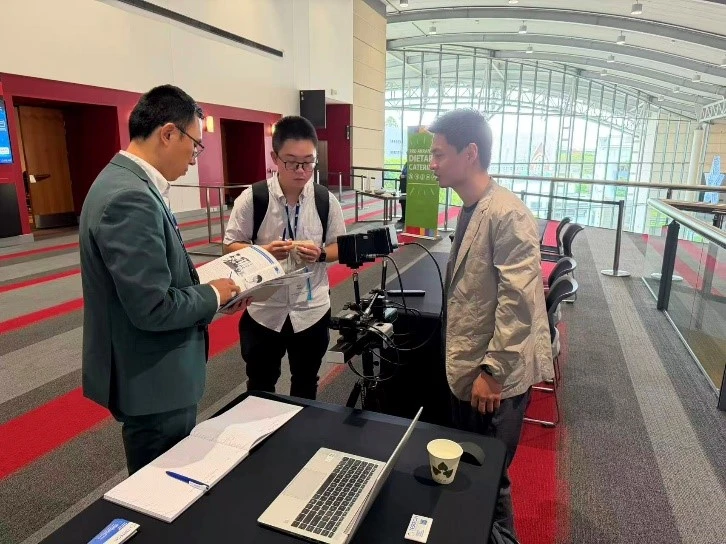

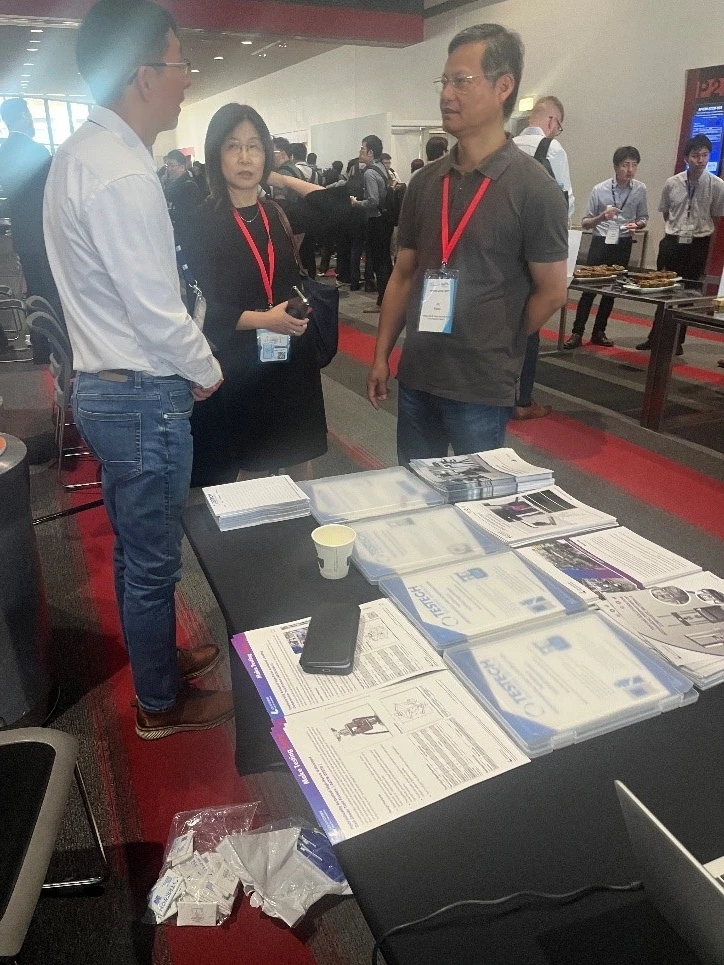

At this prestigious mechanics conference, Xtop 3D engaged with experts, scholars, researchers, and university students from across the Asia-Pacific region to explore emerging technologies and applications in mechanics.

The company showcased the exceptional performance of the XTDIC-CONST Series 3D full-field strain measurement system in material characterization, component testing, and motion analysis, while seeking collaborative opportunities to advance scientific research and engineering applications to new frontiers.